Swedish low-carbon battery startup Northvolt is on a bit of a roll lately. Recently, the company revealed a new collaboration with Scania to produce the longest lasting EV batteries on the market. Now, its wholly-owned subsidiary Cuberg has unveiled a program to develop high-performance batteries to achieve “safe and sustainable” electric flight.

One of the biggest stumbling blocks to zero-emission electric aviation is, apart from access to renewable energy, battery technology. Today’s batteries are, simply put, too inefficient and too heavy.

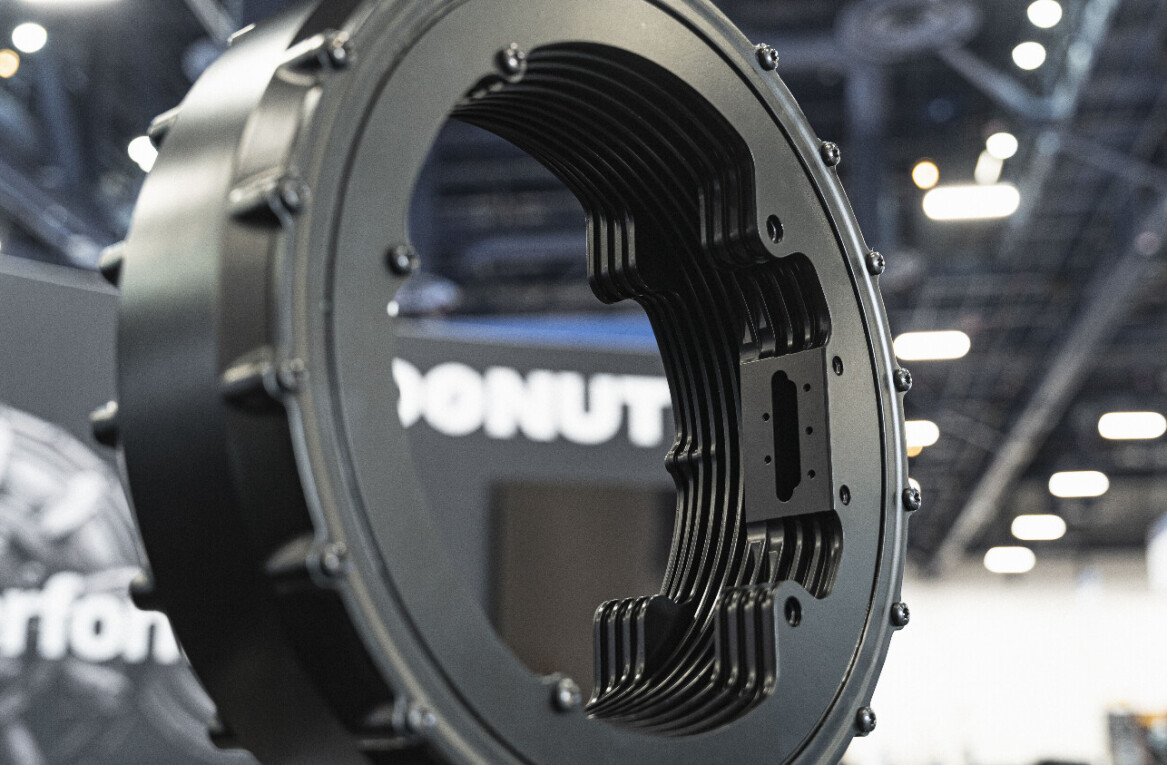

However, Cuberg says it has already achieved significant milestones in its next-generation lithium metal cell battery technology. This involves a lithium metal anode and proprietary liquid electrolyte, which the company says simultaneously solves the interlocking challenges of battery performance and manufacturability.

Furthermore, Cuberg says it will have “superior power and energy capabilities to today’s conventional lithium-ion batteries.” The aim is to develop a breakthrough lithium metal cell boasting an energy density of 1000 Wh/l by 2025.

Significant achievements thus far include building and shipping a 20 Ah commercial-format lithium metal pouch cell with specific energy of 405 Wh/kg. Furthermore, the company has engineered and produced an aviation module based around the 20 Ah cells, with specific energy of 280 Wh/kg and energy density of 320 Wh/L.

Importantly, the module platform has achieved what is called passive propagation resistance during a verification test campaign, which means it can resist the spread of a thermal runaway event from one cell to another.

Thermal runaway is one of the biggest safety concerns with lithiummetal cells, as it may cause the battery to catch fire or explode. As such, the verification is considered a key step when certifying batteries for aviation.

Expanding lithium metal cell cycles

Meanwhile, lithium metal batteries, as opposed to lithium-ion, can only be recharged a few times before they become unusable. This may be cause for other sustainability concerns, given the environmental costs of lithium extraction.

However, in a third-party validation in July last year, Cuberg’s cell cycle life was confirmed to have been extended to 672 cycles, with energy capacity of 380 Wh/kg, making it the world’s highest-performing and longest-lived lithium metal cell in a commercially representative cell size.

Northvolt ranks first on the list of most-funded startups in Europe, with a total of €5.5bn raised to date. Furthermore, it has secured more than €50bn worth of contracts from customers including BMW, Fluence, Scania, Volkswagen, Volvo and Polestar.

Northvolt acquired Cuberg, founded in 2015 and based in San Leandro, California, in 2021 to help bring the startup’s next-generation lithium metal cell technology to scale.

Playing the long sustainable aviation game

Proportionally, aviation, as an industry, is not that big a polluter; it is responsible for “only” approximately 2.5% of global greenhouse gas emissions. This can be compared to transport as a whole (14%) and other industries such as agriculture, forestry and land use (24%).

However, as other industries begin to decarbonise, the difficult-to-abate aviation sector’s share of emissions will expand. What is even more alarming is that global passenger traffic is predicted to reach 19.3 billion by 2041, up from a forecasted 8.4 billion in 2023.

It is true that the lion’s share of emissions come from long-haul air travel, and aerospace engineers may be a long way yet from coming up with a zero-emission high-capacity propulsion system.

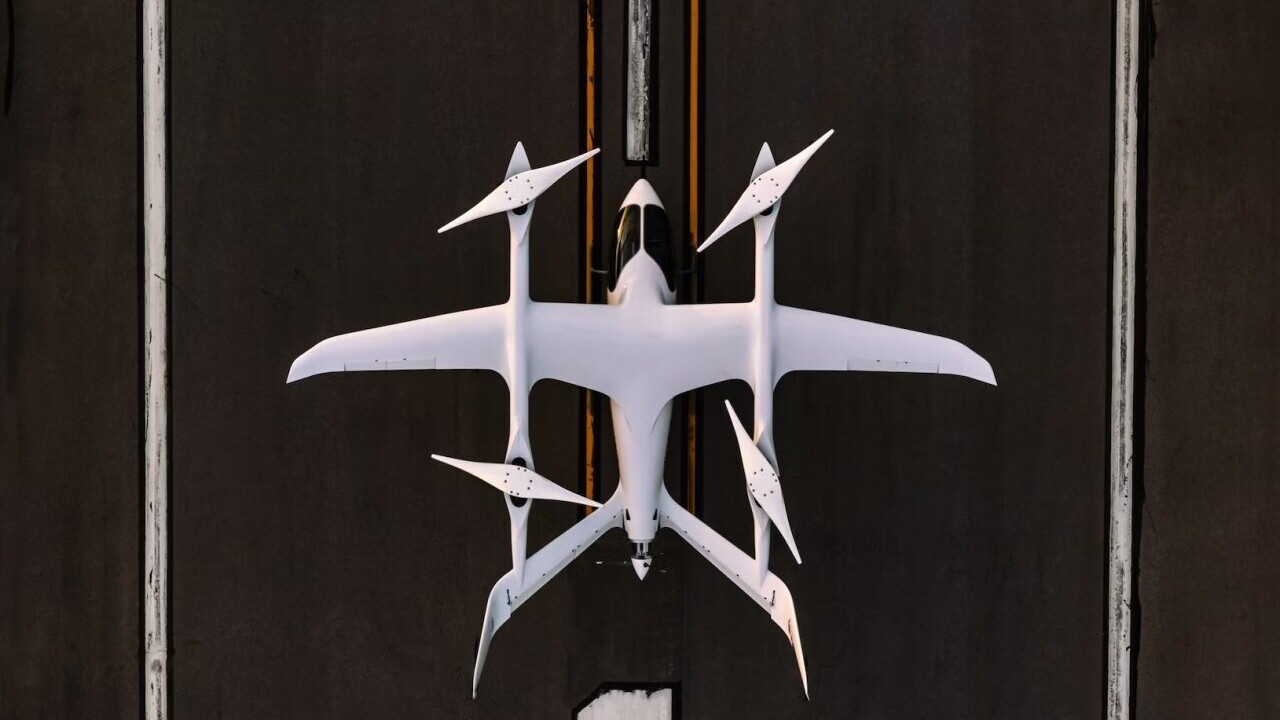

Meanwhile, innovation must start somewhere. Technology being developed today for the lower capacity regional air travel segment will serve as the foundation for more sustainable narrowbody and dual-aisle aircraft further down the road.

As such, the immediate effect of replacing short-haul aircraft with electric or hydrogen-electric planes may not be globally significant. However, the extrapolated implications of developments in areas such as battery and fuel-cell technology coupled with energy storage may just be one of the avenues to solving aviation’s fossil-fuel dependency.

Countries such as the UK, Norway and Sweden have already set deadlines to entirely decarbonise domestic aviation within the next couple of decades. Swedish electric aircraft startup Heart Aerospace has received firm orders for 230 of its 30-seat ES-30, along with options for another 100 and letters of intent for additional 108 units. The plane is scheduled to enter service in 2028, with a scalable upgrade path as “future battery technology matures.”

Furthermore, the global electric vertical take-off and landing vehicle (eVTOL) market has around 500 developers. Specifically, Cuberg has already received orders from established companies such as Boeing and urban air mobility (UAM) startups including BETA Technologies, Ampaire and Volt Aero. The company says it will deliver modules to select aviation customers throughout 2023.

Get the TNW newsletter

Get the most important tech news in your inbox each week.