Battery-powered vehicles are the future. Whether it’s EVs, ebikes, or escooters, going rechargeable is the way forward.

However, not everything is rosy with this model.

For all their green cred, most ebike batteries only last three to seven years, and cannot be easily recycled or their precious materials recovered.

Currently, the glue or welding used in designing battery packs makes it challenging to refurbish or replace cells or components within a battery.

Fortunately, this may change — because a French startup called Gouach has created a new repairable battery for micromobility vehicles.

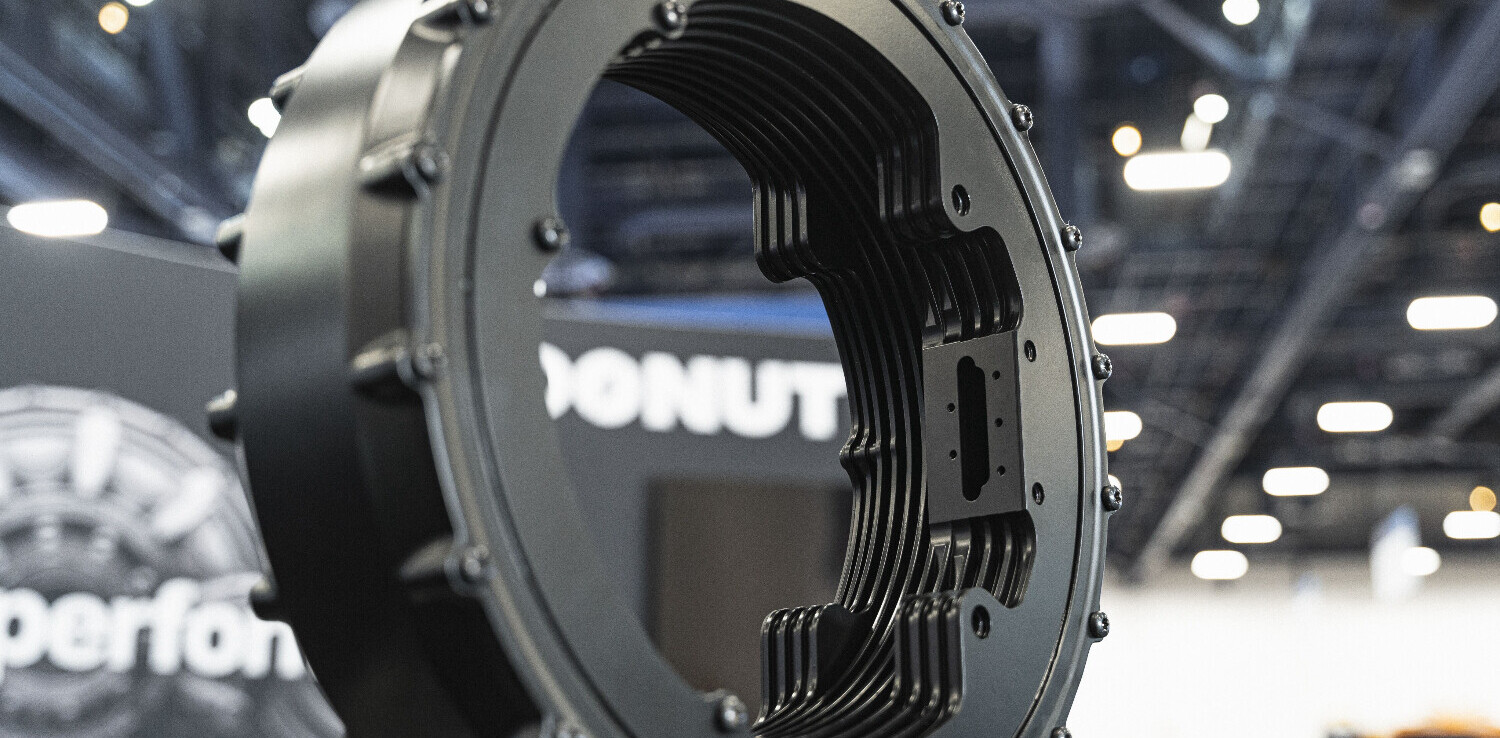

It uses a modular, solder-less design in its batteries. This means that the electronics and cells can be changed easily. This also removes the risk of damage to the cells. This allows for an increase in battery longevity. It also reduces its carbon footprint by as much as 70%.

Their repairs take less than ten minutes at a cost of €5-€10 ($5.60 -$11.20). By comparison, it costs around €200 ($220) to replace a complete battery.

And the industry has taken note, with Gouach recently raising €3.3 million ($3.7 million) in seed funding.

The modular design means all batteries parts can be dismantled and fixed.

Dott uses repairable batteries to help close its battery loop

Micromobility provider Dott is using the repairable batteries on its ebikes and escooters. Their modular design makes it easy to disassemble and repair batteries with minor defects and get the batteries back into its vehicles.

As the company asserts:

As a result, we can extend the lifetime of our batteries and significantly reduce the number of [them] we have to find second-life applications for, as they keep being looped back into our own operations.

It’s terrific to see companies making further steps towards sustainability. However, there needs to be more pressure for repairable batteries becoming a reality on the regulatory side.

Research conducted by the International Institute for Industrial Environmental Economics (IIIEE) the European Environmental Bureau (EEB), and the Right to Repair campaign late last year found that software locks hinder battery refurbishment.

They discovered that ebikes designed and manufactured by Bosch, Yamaha, and Specialized are examples of brands that use software locks.

Furthermore, while battery cells have a standard format (18650 being the most popular), the battery packs and management systems are tailored to manufacturers and sometimes to specific bike models, creating barriers to repair and replacement.

EU legislation would help solve this issue across the region. If ebike makers and manufacturers had to abide by regulations regarding the right to repair, refurbishment, and responsible recycling, this would advance true electric battery sustainability.

A rechargeable future is possible and inevitable — but there’s still a lot to do to ensure that the impact can represent the growth of ebikes and escooters.

Get the TNW newsletter

Get the most important tech news in your inbox each week.