Helixx has a unique vision of urban mobility. The British startup has engineered a range of affordable electric vehicles. The company also designed a manufacturing system for the EVs. But Helixx doesn’t plan to actually build the cars. Instead, it wants Helixx customers to build them.

At first glance, that may look like a lazy strategy. But the pitch has an intriguing foundation: a “factory in a box” that clients use to produce cheap EVs from almost anywhere in the world.

The project promises rapid results. According to Helixx, the system can take a local business from an empty building to finished vehicles in just 180 days.

The Helixx concept applies the McDonald’s franchise model to vehicle production.

The digital production ecosystem is supplied to businesses, entrepreneurs, and local governments as a manufacturing license. The licensees then become the official vehicle manufacturers.

“It removes the need to know how to manufacture vehicles.

To start the process, Helixx designs the factories — called mobility hubs — around the customer’s market demands, space allocations, and budgets. The software platform then aggregates the necessary assets, including architectural support, digital operations platform, processes, and training.

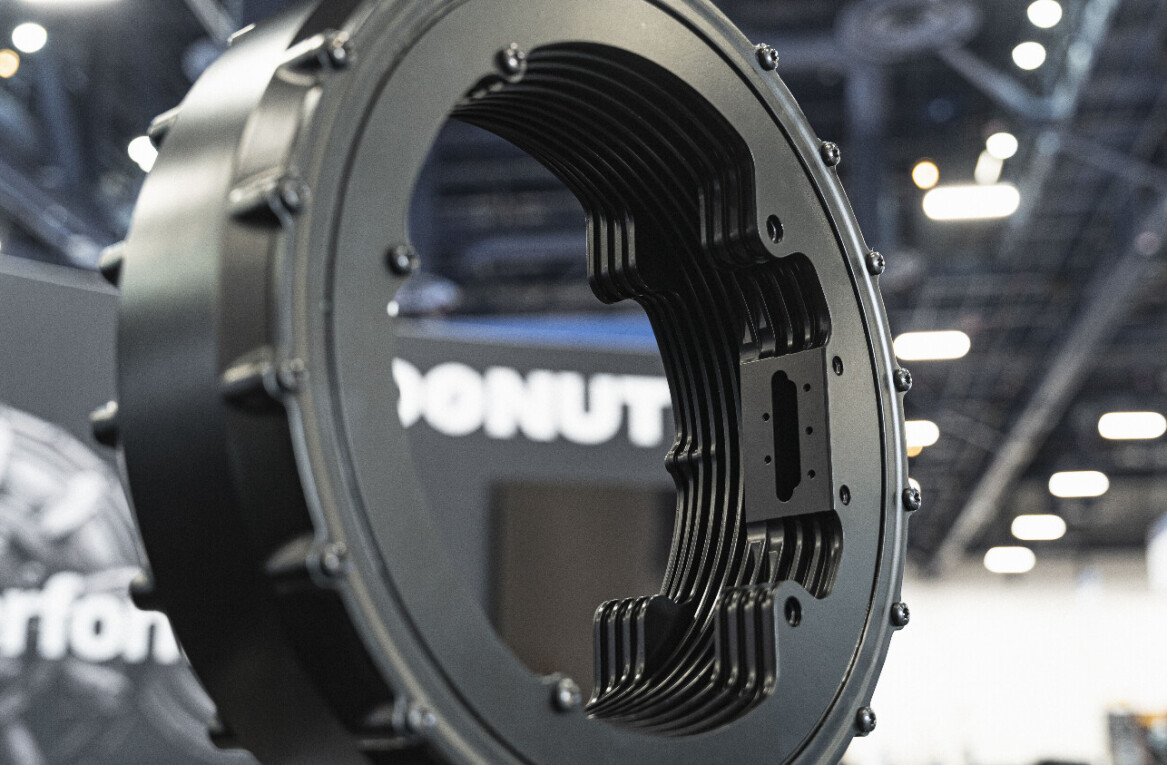

Helixx also provides the infrastructure, equipment, robotics, and IT systems. All of this is installed and commissioned to the startup’s cloud within six months — ready for the hub to begin assembly.

Once a hub is operational, it becomes fully integrated into the Helixx ecosystem. An app then manages the entire end-to-end process, from customer orders to component procurement and delivery.

As the entire process takes place within a single environment, clients bypass the costs and complexities of developing both vehicles and manufacturing systems. Steve Pegg, the CEO of Helixx, said this approach democratises EV production.

“The aim.. is to remove the necessity for Helixx licensees to know how to manufacture vehicles, as this is all managed by the intelligent technology platform,” Pegg told TNW. “As the platform matures, so will the product portfolio, with Helixx adding further vehicles in the future.”

Helixx is targeting the system at densely populated regions of emerging markets. According to the UN, two-thirds of the world’s population could live in urban centres by 2050 — a total of 6.6 billion people. Many of them will live in megacities of developing countries.

Helixx is betting that they’ll flock to small, affordable, and zero-emission vehicles. If they’re built locally within a circular manufacturing ecosystem, costs can be cut, sustainability enhanced and new economic opportunities unlocked.

“The densest cities of the world will struggle to build a robust infrastructure to support the volume demand,” said Pegg. “The overall cost of consumer vehicles and electrified choices we see today are mostly out of the price range.

“The Helixx vehicles address all of the sensitive points around implementing EVs into the working fleets by offering them as pure subscription — not leased, or financed disguised as subscription — and by utilising small battery swap services.”

The vehicles will be offered at a rate starting at $0.25 per hour. Operators can also subsidise revenue streams through e-ink advertising panels and data-as-a-service models

Helixx has pledged to provide customers with extensive support.

To optimise operations at every hub, all the data is monitored in real-time at Helixx Mission Control in the UK. Any efficiency trends that emerge can be shared with other partners. As everything falls within the Helixx ecosystem, hubs can also trade with each other.

Further efficiencies will be driven by automation. When components need upgrading, AI programmes will automatically trigger maintenance or replacement within the digital supply chain.

Helixx has also integrated the Siemens Xcelerator. The software suite can create a digital twin for every element of the manufacturing ecosystem. As a result, each stage of the process, from site survey to manufacture and vehicle recycling, can be modelled and validated before it’s rolled out.

Teruyoshi Adachi, CTO of Helixx, said the software will “weave digital threads through the entire fabric” of the company’s business model. He estimates that the costs and complexity of the entire operational chain have already been reduced by 20%.

Helixx still needs to prove the digital ecosystem works in the physical world. The concept hub has already been successfully tested at Helixx’s headquarters in Oxfordshire – the world’s biggest hub of motor racing. The startup is now establishing pilot hubs in the UK and Singapore.

If that goes to plan, it will take Helixx a step closer to its ultimate objective: the creation of a brand-new transportation segment.

Get the TNW newsletter

Get the most important tech news in your inbox each week.