3D printing is awesome. But it also kind of sucks.

3D printing allows you to build all sorts of gadgets and gizmos, fix things without having to locate specialty components, and solve problems you didn’t even realize you had. You can build sporks! Folding coat hangers! Ratchet wrenches! Wheelchairs for dogs! If it has a shape, you can probably print it.

But 3D printing is slow. Until I tested my first 3D printer – one of the most highly-regarded on the market, mind you – I don’t think I really grasped how much patience is required to iterate on a design. Large prints are often measured in days, not hours, especially if you plan on printing at optimal quality.

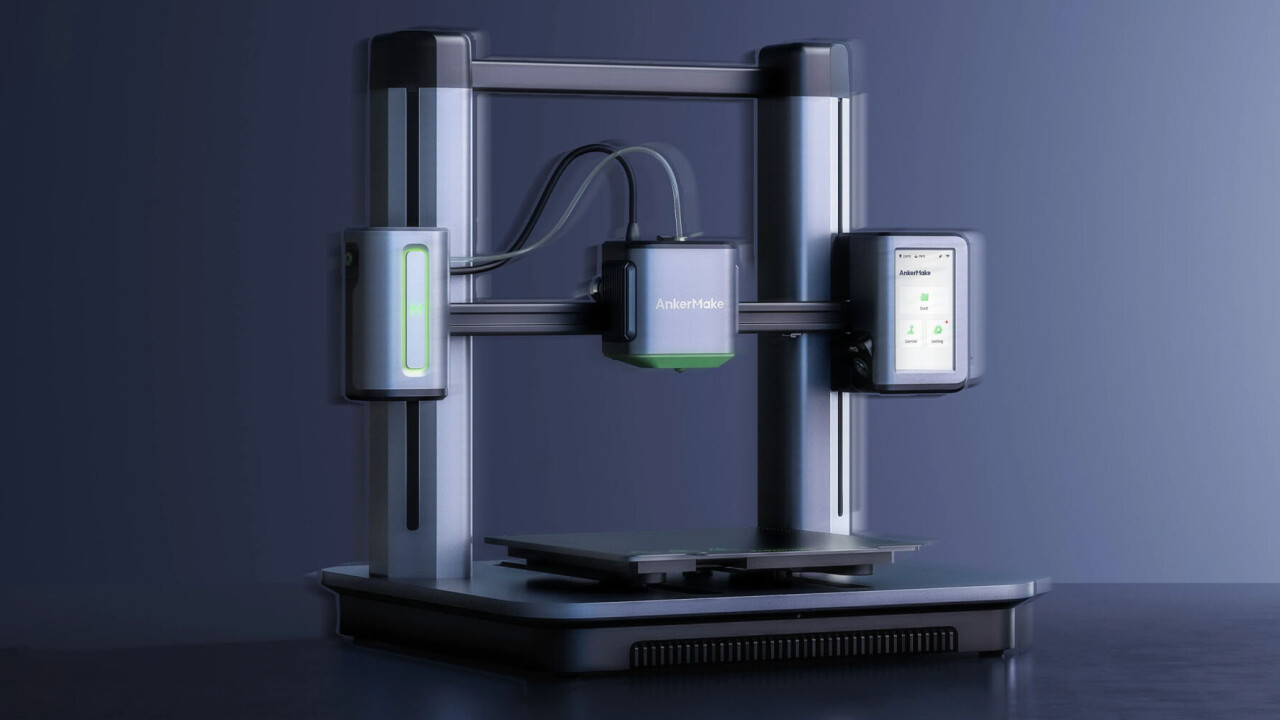

Anker, the company best known for its chargers, batteries, projectors, and headphones, wants to solve this problem with its new 3D print brand, AnkerMake. The AnkerMake M5, live on Kickstarter for $599 (MSRP $759), claims to be a whopping five times faster than some of its biggest competitors while retaining similar quality. Big, if true.

We’re generally wary of Kickstarter campaigns here and only cover them if we’ve been able to test a prototype or the company is an established brand with a history of delivering products to consumers. Anker falls into the latter camp, and if it didn’t we probably wouldn’t bother to cover such an outlandish claim. But color me curious.

For reference, a typical printer has a standard print speed of about 50mm/s at high-quality settings. AnkerMake M5 defaults to 250 mm/s. You know, five times faster.

I should clarify that pretty much any 3D printer can be made to print at those speeds. There’s an entire community of YouTubers who race to perform common test prints as quickly as possible. But these folks are typically using custom parts and numerous tweaks to achieve that efficiency.

Unless you really know what you’re doing (or it’s a very simple print), printing at 250 mm/s usually won’t be very good. That’s especially true if you’re using a fine detail setting of 0.1mm.

AnkerMake says it’s able to achieve these speeds with a fancy “ultra-direct” extruder (the moving ‘head’ that heats up and prints plastic). It supposedly uses a higher gear ratio, a larger heating block, and cools prints more quickly than the competition. The latter is particularly important, as a print simply won’t maintain its shape at high speeds if the plastic can’t cool down and harden quickly enough.

The company also says that it’s using an extra-heavy base for additional stability, as well as a double-belt driveshaft and a motion stabilization algorithm to minimize vibrations that could throw off a print.

Fast prints aside, the M5 also adds a number of convenience features, including built-in WiFi (some printers don’t have this), quick assembly, and a built-in camera that can detect printing errors and alert you to printing status via your phone.

There’s a night-vision mode to continue tracking your print after the sun goes down, as well as a timelapse mode so you can share your creations on social media. And AnkerMake says the printer is even pretty quiet too.

This is definitely one of those ‘the proof is in the pudding situations’ but boy do I want a taste of that dessert. High-quality prints at these speeds would be the equivalent of getting broadband after living with dial-up your whole life (the dark ages, Gen Z). It’s hard to imagine a new entry to the market could have made such a massive leap so quickly.

I’m also concerned about the repairability of the units; the M5 has a unique design, but one of the nice things about many top 3D printers on the market is the ability to fix and upgrade devices with aftermarket components.

Still, if Anker’s speed claims are realistic, it could open up 3D printing to a much larger audience (the audience that doesn’t have the patience for day-long prints). Anker seems to have earned enough of its users’ trust already: the Kickstarter has already met its goal with over $2,000,000 in funds and nearly 3,700 backers at the time of publishing this article.

Get the TNW newsletter

Get the most important tech news in your inbox each week.